OUR WORKSHOP

From raw fiber to exceptional duvets

Before becoming filling, each alpaca wool fiber undergoes a demanding and respectful process.

It all begins with meticulous dusting, where natural impurities (dust, plant matter) are removed without aggressive treatment. This is followed by washing with clear water and organic soap, without chemicals, to preserve the wool’s softness and thermoregulatory properties.

Once clean and dry, the wool is hand-sorted: only the finest, softest, and most uniform fibers are retained.

They are then carded, an ancestral mechanical process that aligns the fibers and creates an airy, lightweight structure. This uniform wool batt is ideal for ensuring natural and balanced thermal insulation throughout the Eraen duvet.

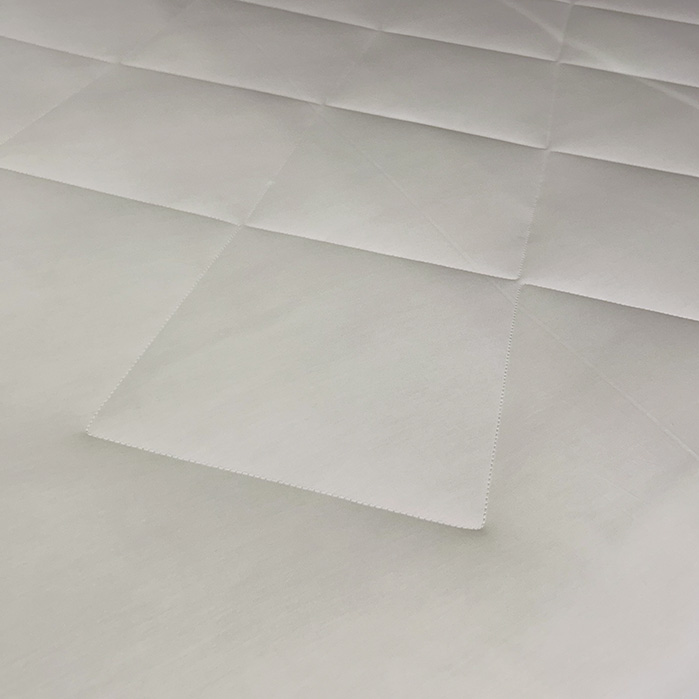

Finally, in our workshops, this filling is integrated into a high-end cotton percale casing, then precisely quilted to ensure perfect fiber stability over time. Each duvet is manually inspected before leaving the workshop.